Siemens Digital Industries Software today set the benchmark for innovation in the field of engineering simulation with the launch of two groundbreaking solutions - HEEDS™ AI Simulation Predictor software and Simcenter™ Reduced Order Modeling software. These tools empower engineers to tackle the most complex challenges manufacturers face, delivering predictive performance with speed, precision, and efficiency.

Siemens' HEEDS AI Simulation Predictor unlocks new possibilities for manufacturers by empowering engineering teams to harness the potential of advanced AI-driven predictive modeling. As a new addition to the Siemens Xcelerator portfolio, it can revolutionize design space exploration.

Key Advantages:

- Optimize products with precision: HEEDS AI Simulation Predictor harnesses state-of-the-art AI with built-in accuracy awareness helps organizations to fully leverage the digital twin to fine-tune and optimize their products with unprecedented precision.

- Faster, more innovative designs: By tapping into historical simulation studies and accumulated knowledge, engineering teams can swiftly craft high-performing, innovative designs, significantly reducing time-to-market.

Addressing the AI drift challenge

One of the most significant challenges in AI-powered simulation is AI drift, where models extrapolate inaccurately when faced with uncharted design spaces. To address this challenge, HEEDS AI Simulation Predictor introduces accuracy-aware AI. This new technology actively self-verifies predictions, aiding engineers to conduct simulations that are not only accurate but also reliable in the context of real-world industrial engineering applications.

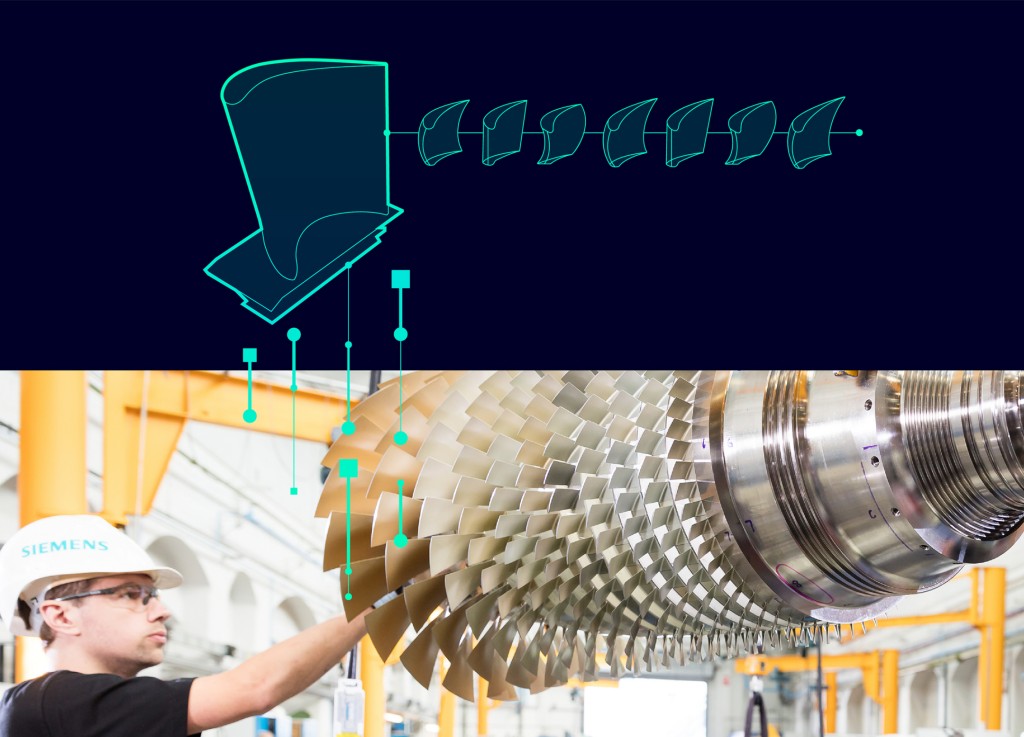

“With HEEDS AI Simulation Predictor, we have significantly improved various components of the gas turbine, leading to highly optimized designs and accelerated design cycles,” said Behnam Nouri, Team Lead, Engineering & Platform Design, Siemens Energy. “Our thermo-mechanical fatigue predictions have been effectively upgraded to process ~20,000 design members in only 24 hours, yielding a 20% improvement in component lifetime. This has allowed us to fully characterize the limits of our existing design space which is required for high-efficiency turbine engines. The HEEDS AI Simulation Predictor technology has enabled us to save over 15,000 hours of computational time.”

Siemens today also introduces Simcenter Reduced Order Modeling, new software that harnesses high-fidelity simulation and test data to train and validate AI/ML models. These models then enable engineers to perform predictions in a fraction of a second, transforming the way engineering professionals approach simulation.

Key Advantages:

- Speed and precision: Simcenter Reduced Order Modeling uses high-fidelity data to empower engineers to gain rapid predictions and to make critical decisions in a fraction of the time it would take using conventional methods.

- Predictive performance: By training AI/ML models on comprehensive datasets, this technology enables engineers to gain robust, reliable, and trustworthy insights, helping to eliminate the common issue of AI drift.

“Simcenter Reduced Order Modeling lets us accelerate our simulation models to the point where a detailed fuel cell plant model runs faster than real time, with the same accuracy as a full system model,” said Jurgen Dedeurwaerder, Simulation Engineer, Plastic Omnium. “This enables activities such as model-in-the-loop controller development and testing to be done faster, shortening the overall development cycle by around 25%. At the same time, it gives us a reliable, IP protected, and cost-effective way to distribute models to other teams, both internally and to our customers to augment their own products and processes, resulting in better quality products delivered to end users.”

“HEEDS AI Simulation Predictor and Simcenter Reduced Order Modeling represent a true breakthrough in simulation technology. They enable our customers to take advantage of benefits of artificial intelligence-driven simulation to speed their exploration of a design space and to do so accurately and robustly,” says Jean Claude Ercolanelli, Senior Vice President, Simulation and Test Solutions at Siemens Digital Industries Software. “It also enables them to not only use these breakthrough technologies on new projects, but to leverage decades of past simulation data to help deliver new insights on current projects.”

To learn more about how Siemens Digital Industries Software is making a significant leap forward in the quest for reliable, trustworthy AI-driven simulations and pushing the boundaries of what's possible in simulation technology, visit the What’s new in HEEDS and SIMCENTER Reduce Order Modeling blogs.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens' software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today's ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digitial Industries Software – Accelerating transformation.

Source: Siemens