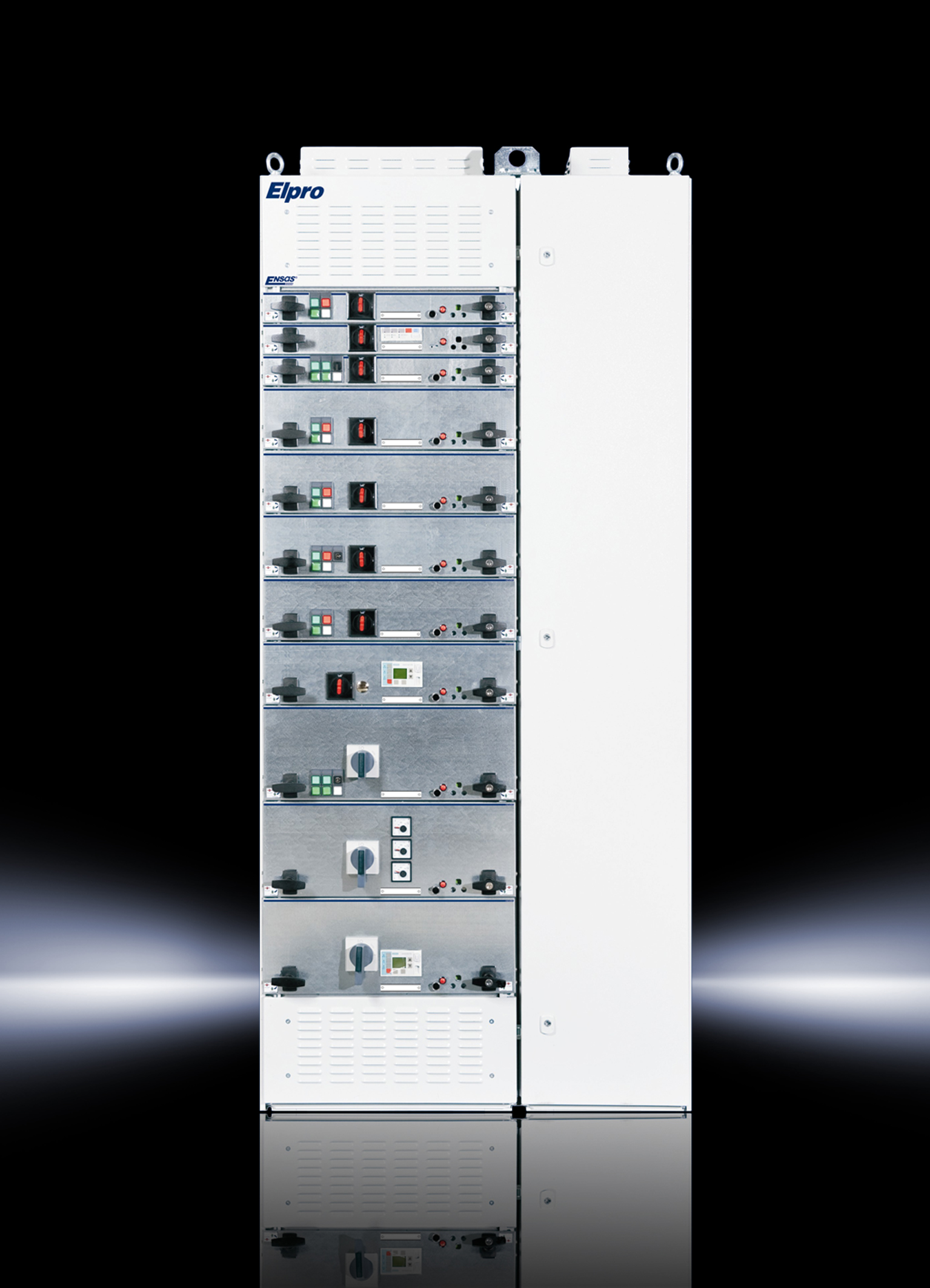

In a system partnership with Rittal, Elpro - a specialist in electrical systems and control technology - has now developed a new fully withdrawable system based on Ri4Power. Elpro will be distributing it as the ENSAS 5000 switchgear system in the future.

In order to achieve high-availability switchgear, Elpro has now developed a new system - ENSAS 5000 - based on Rittal's Ri4Power, which has been extended by the addition of withdrawable outgoing sections. Full assemblies such as motor starters can be easily replaced in the event of service work being carried out, without the unit having to be shut down.

In order to be independent of the licenses and product policies of other companies with the new system, and after conducting European market research, Elpro decided on Rittal as its system partner in enclosure technology. Customers who choose a switchgear installation based on the tested and machine-independent Ri4Power system benefit from the fact that they remain sovereign in their choice of switchgear manufacturer.

The modular Ri4Power system, upon which the withdrawable technology is based, allows an internal separation of the individual sections, as well as a partitioning of the cable connection space. The withdrawable modules developed by Elpro are available in a variety of heights on a 75 mm pitch pattern. The largest modules with six height units (U) are 450 mm high. A total of 22 modules per enclosure are possible with the smallest height. Rated current can be up to 5,000 A, and the entire system is type tested to IEC 61439-1/-2.

A patented technology is used for the withdrawable equipment, in which the contacts to the busbars are made not at the far end of the withdrawable equipment - as with other currently available systems - but laterally. For this purpose, a contact system is mounted on the withdrawable equipment that is introduced into the corresponding counterpart in the enclosure by means of a special rail guide.

The advantage of this system is that the modules can be slid effortlessly into the enclosure. The contact is made with a lever on the front panel. If withdrawable equipment is removed from the enclosure, an automatic shutter system ensures that the busbars are covered to prevent accidental contact.

The busbars are encapsulated over their entire length, so ensuring that the system is free of arcing faults. Using the lever, the withdrawable equipment can be placed in the "Test", "Operation" or "Separate" positions, which can each be mechanically latched and locked.